gearbox cvt for Dummies

gearbox cvt for Dummies

Blog Article

With CVTs, just one worry may be the likely for “rubber band” sensation throughout acceleration, which some drivers obtain unpleasant.

On the list of More moderen CVT improvements, it makes usage of dynamic inputs like software speed, auto pace, and pedal posture. These aspects add to identifying the right equipment ratio, causing constant and sleek acceleration.

The most obvious application for just a CVT is if you’re attempting to make sure highest gasoline efficiency, hence why Subaru has paired Boxer engines and all-wheel travel (all-wheel drive adds pounds and may have an effect on fuel consumption driving up the relative gasoline intake of the Subaru in comparison that has a non-AWD SUV in the same segment) by using a CVT.

New motor vehicles with CVTs should really work dependably for approximately one hundred,000 miles out there currently. Over-all dependability for the majority of autos will be lower than what on earth is predicted with a typical computerized or manual transmission.

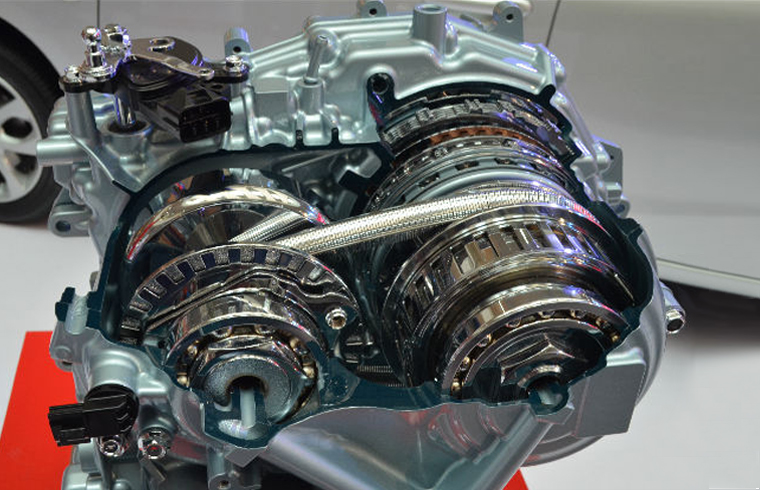

The belt for most CVT devices can be a hefty responsibility “V-belt” and that is V-shaped in cross section. They are really fabricated from rubber components bolstered with Kevlar together with other materials to reinforce durability.

This portion requires additional citations for verification. Remember to support improve this post by introducing citations to reliable sources In this particular portion. Unsourced materials could be challenged and taken out. (July 2020) (Learn the way and when to eliminate this information)

The end result can be a smoother, far more productive and a lot quicker generate than an typical automated. There's a downside though, Which’s the Electrical power losses as a consequence of friction are bigger that has a CVT – about five to fifteen% depending upon the kind, While with typical gears it’s a lot more like two-five%. As ever, growth is closing the gap, and the fact the CVT allows the motor to remain in its ideal rev changes a lot more than compensates for the extra efficiency loss.

On the flip side, eCVTs are suitable for hybrid and electric automobiles. They don’t use belts. Rather, they use electrical motors as well as a planetary gear system to manage energy between the motor plus the wheels. This layout is observed in automobiles such as Toyota Prius, which happens to be recognized for its resilient eCVT program.

This distinction is not just technological but sensible, offering drivers a smoother Using expertise without the typical change shocks present in standard units.

I'm the founder of Day by day Automobile Guidelines. I wrote content within the automotive marketplace for a lot more than 10 years, revealed in United states of america and Europe. I love sharing my know-how and insights with fellow enthusiasts. Be part of me on this journey as we explore the enjoyable globe of cars and trucks collectively! View all tips seterusnya posts

A standard automatic gearbox works by using gears to match engine pace to highway speed. At very low speed, the engine turns a small equipment which is connected to a larger equipment that turns the wheels by way of other transmission components.

CVTs are shockingly straightforward parts of engineering which have considerably fewer shifting sections than traditional automatic transmissions. They function through the use of a series belt that connects two sheaved conical pulleys, with one of the pulleys becoming the input with the motor.

Still in advancement, the magnetic CVT transmits torque utilizing a non-Call magnetic coupling.[thirty] The design utilizes two rings of everlasting magnets that has a ring of metal pole parts between them to create a planetary gearset making use of magnets.

CVTs supply a consistently variable gear ratio to help keep the car’s motor operating within just its optimum rpm vary for just about any driving situation. Often often known as a shiftless, stage-fewer, or solitary-velocity transmission, just one-equipment CVT differs from a traditional automated transmission by furnishing several equipment ratios. Although Leonardo da Vinci made the first CVT in 1490 and Daimler and Benz patented their layout in 1886, the recognition of CVTs has snowballed over the past several years.